MIXING SYSTEM

patented

Machines for processing products that mix media in a low to high viscosity, solid or gaseous state into a product mass in a low to high viscosity or gaseous state are widely used. These systems usually have a rotor as a mixer, i.e. they work rotationally. Or they have a linear mixer that moves in the axial direction. The systems require a constant pressure. In applications where a clocked filling machine or other dispensing device follows, the pressure and volume must be regulated. In the case of pressure stabilisers, there are the familiar systems with diaphragm and piston, which are pneumatically controlled and are usually limited in capacity and generally too inaccurate, or the systems with pistons, which are very expensive and not easy to clean.

In all cases, the drive shafts must be routed from the outside to the inside of the mixer chamber to the rotor mixer or piston, etc.

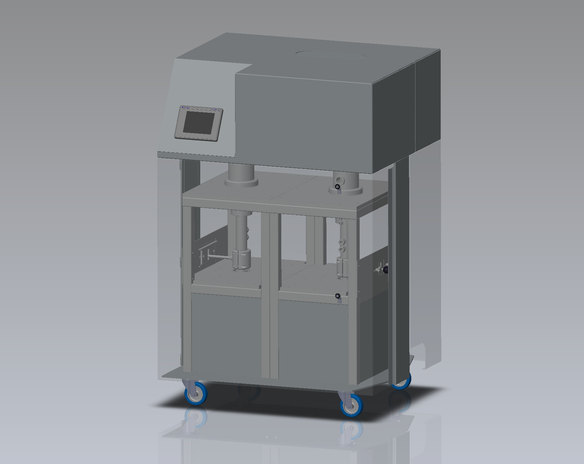

The new generation of Mixing System

Our mixer head has an oscillating mixing chamber that allows the gasand product to be mixed in a particularly gentle way. Depending onthe mixing head speed and the design of the mixing tools in themixing head, very high shearing of the product is possible. This typeof mixing also provides more parameters for controlling the mixingprocess. This type of mixing makes it possible to processingredients, whole pieces such as fruit pieces, chocolate chips etc.as well. The Knobel linear oscillation principle for the productionof whipped foods offers a clear advantage, especially fortemperature-sensitive products such as fat creams, chocolate andprotein products.

With us, you geteverything from a single source.

Mixer system,particle feed (e.g. hazelnuts), stabilisers and depositors that canfill aerated products with additives. All patented systems.